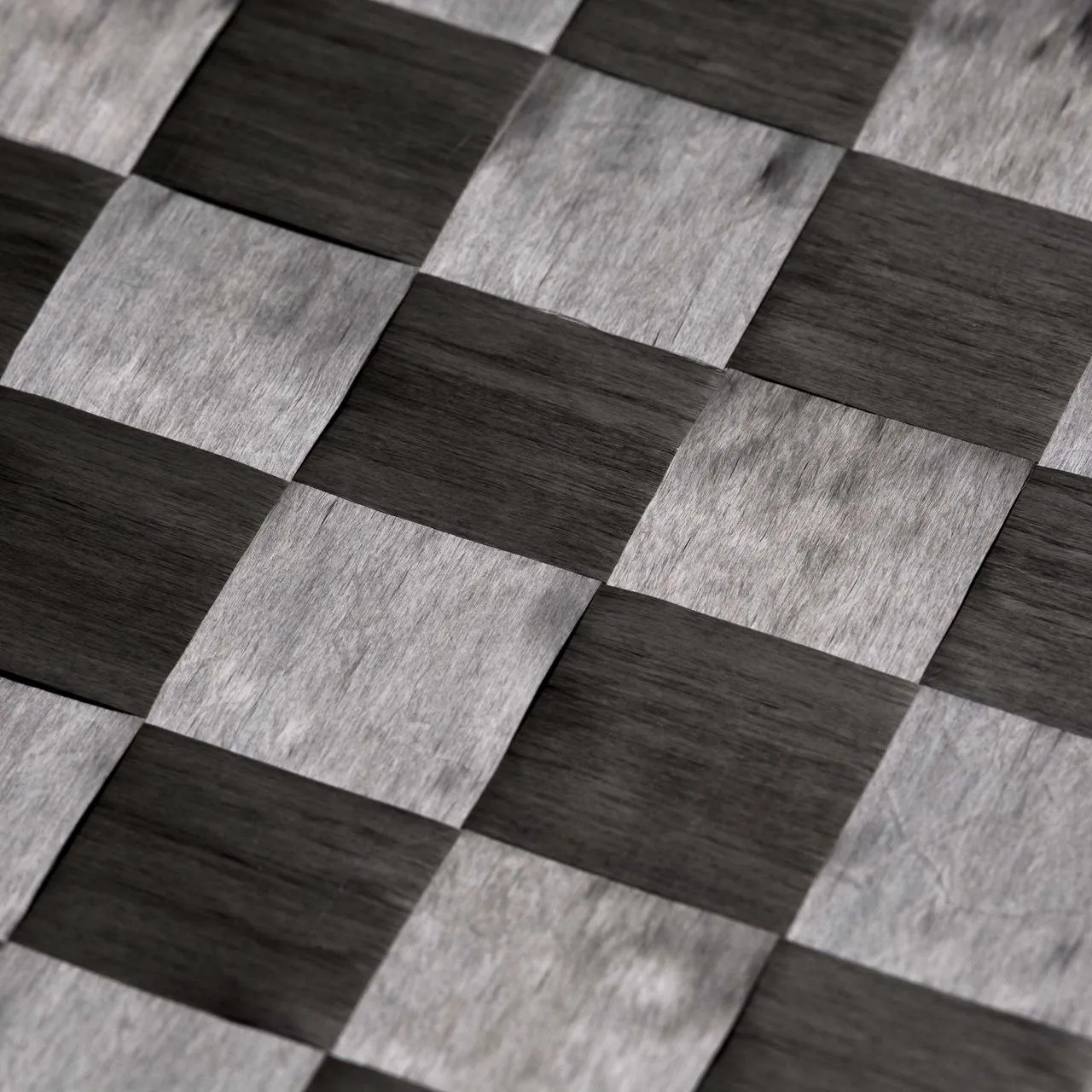

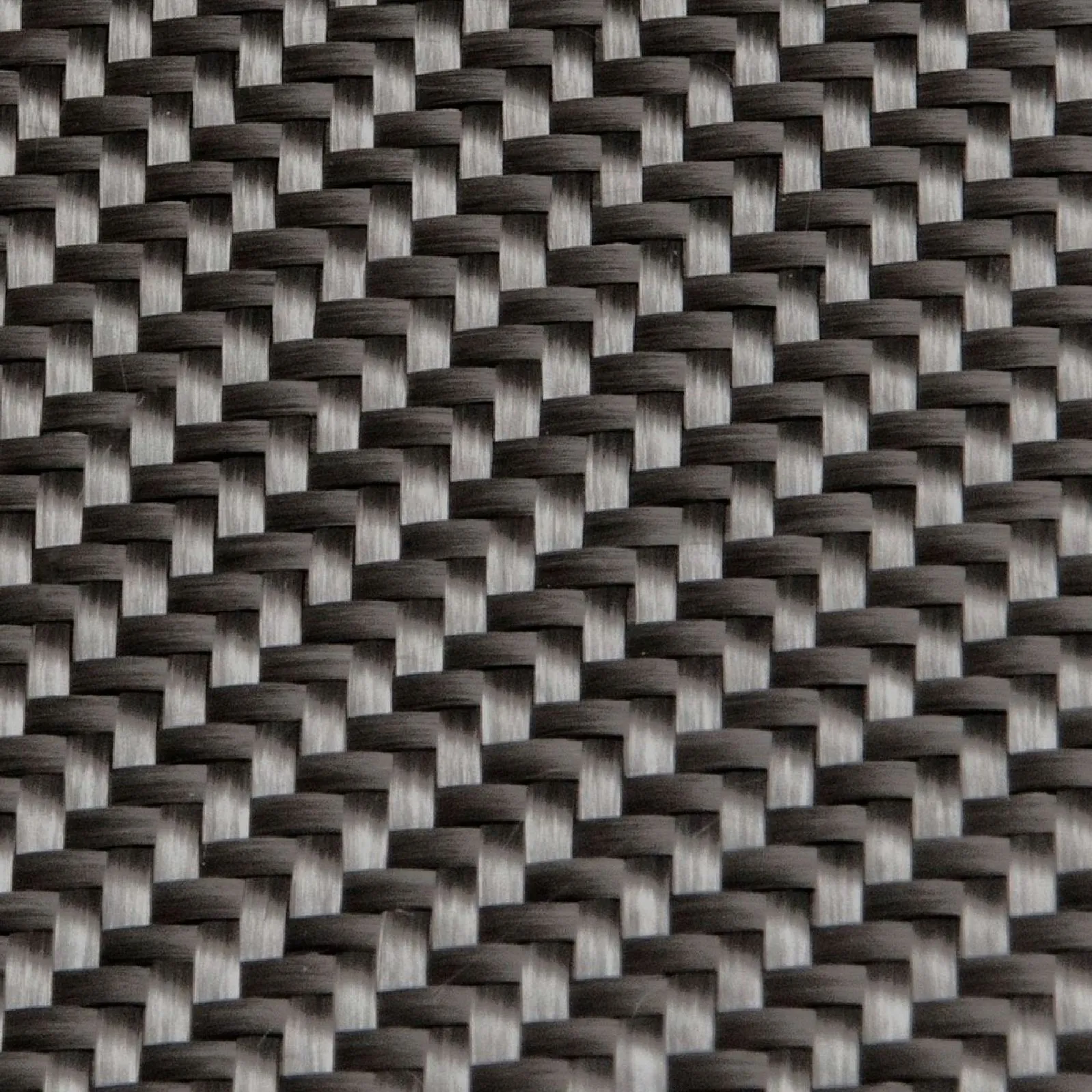

MultiAxial fabrics are advanced textile materials engineered with multiple layers of fiber oriented in various directions. This unique configuration enhances the mechanical properties of the fabric, providing superior strength, stiffness, and resistance to fatigue, making them ideal for applications where performance is critical.

Key Features:

- Multi-Directional Strength: The fibers are arranged in multiple axes, which allows the fabric to equally distribute loads and resist deformation from various angles.

- Lightweight Composition: Despite their robust properties, MultiAxial fabrics are typically lightweight, making them suitable for applications where weight savings are essential.

- Customizable Properties: The fabric can be tailored to meet specific engineering requirements regarding thickness, fiber type, and orientation, allowing for optimization in different applications.

Applications:

- Automotive: Employed in high-performance vehicles, particularly in structural components and body panels, enhancing safety and performance while keeping weight down.

- Marine: Utilized in the production of hulls and other components for boats and yachts, providing durability and resistance to harsh marine environments.

- Sporting Goods: Incorporated into equipment and apparel for enhanced performance and protection, such as in cycling, skiing, and other outdoor sports.

- Wind Energy: Used in the manufacturing of turbine blades, contributing to improved efficiency and durability in wind energy applications.

Overall, MultiAxial fabrics represent a significant advancement in composite materials, offering a blend of performance and versatility across various industries.